SEMI-CERAMIC PULLEY LAGGING

Corrects Belt Slippage and Premature Wear Semi-Ceramic Pulley Lagging provides the solution when conventional rubber lagging fails to correct belt slippage and wears prematurely.

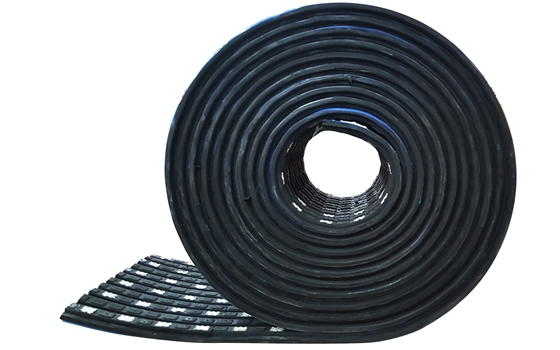

BRITCOs has added a Semi-CeramiC Pulley Lagging to their pulley lagging product line, featuring 40% coverage. The addition of this Semi-Ceramic Lagging allows BRITCO to offer a semi-ceramic product range to provide customers with a choice between full ceramic coverage with our Arrowhead Ceramic Pulley Lagging for a high tensión drive pulleys, as well as less than full ceramic coverage with BRITCOs new Semi-Ceramic Lagging for smaller pulleys, non-drive pulleys and bend pulleys. BRITCOs Semi-Ceramic Pulley Lagging provides the solution when conventional rubber lagging fails to correct belt spillage and wears prematurely. The ceramic tiles are embedded in rubber on all sides and separated by a horizontal groove for dispelling water and dirt. Our pre-chemical backing provides an exceptional bond for rubber-to-metal applications.

Features and BenefitsNewly Improved Ceramic Tile provides robust performance in dry, wet, or muddy applications.

High Grade aluminum oxide ceramic

Bonding Strength that is superior to others, due to 3mm of our neoprene compound vulcanized into bottom-side of the lagging.

Pre-Chemical Backing for ease in installation

Increase Productivity by delivering increased traction between the conveyor belt and pulley, allowing for lower belt tension than with rubber lagging.

Reduce Down Time on non drive pulleys, where pulley change-out due to excessive wear is difficult.

Rounded corners allow for better adhesion between the rubber and the tile.

BRITCO Conveyor Wear LinersWear Liners are designed to be an integral part of any bulk handling conveyor system.

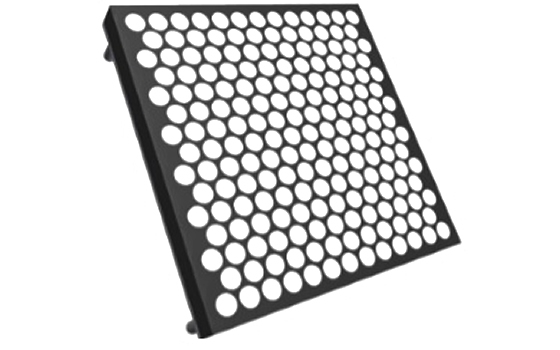

X-BRITCO MINE DUTY CERAMIC CONVEYOR WEAR LINERS Extremely Hard Ceramics For Unsurpassed Resistance BRITCO X-britco Mine Duty Ceramic Wear Liners are made of extremely hard ceramics that provide unsurpassed resistance to abrasive wear while the rubber effectively dampens the impact forces that can crack the ceramic rods. The resilient rubber matrix that surrounds the ceramic rods is hot vulcanized for superior adhesion.

Features and Benefits* Advanced Hard Ceramic Wearplate

* Easy To Install

* Reduces Noise

* Unsurpassed Resistance

* Impact Resistant

* Smooth Surface

* Longest Wear Life Available

* Transfer points in conveyor systems

* Screen chutes

* Deflectors / Feeders

Wide Range of Use -X-Wear Mine Duty Wear Liner is mainly used in the mining and quarrying industries, where severe abrasion occurs and the angles of impact are low.

Excellent Wear Protection for tough mining conditions were there is a need for both wear protection and low noise materials.

1/4´ Steel Backing is suitable for stud welding, plug welding or self-tapping screws.

Plates are available with factory-welded mounting studs for ease of installation.

Typical Examples:

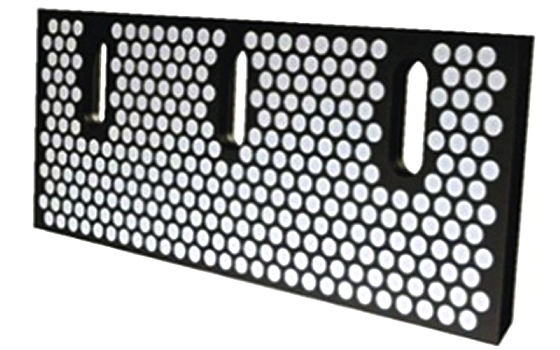

X-BRITCO CERAMIC CANOE SKIRT LINERSEffective For Sealing Inside the Skirtboard and

Adds Stability

BRITCO Ceramic Canoe Skirt Liners are highly effective for sealing inside the skirtboard, controls the material until it becomes stable and protecting the skirt wall from wearing.

The liner is comprised of a ¼´ mild steel backing plate that is vulcanized to an abrasion / impact resistant 60 durometer rubber (or urethane) with a ceramic cylinder (or squares) matrix. The liners have beveled edges to insure optimum sealing inside the skirting and to eliminate spillage and leaks. The modular sections are designed for ease of handling and installation and for easy replacement.

Beveled edge design insures optimum sealing inside the skirtboard to prevent material spillage

Adjustability of the Canoe / Skirt Liners aid in the conformity of the conveyor belt and maximize liner life

Longer wear life Single edge bevel or dual edge bevel for reversible wear life

Custom sizes, thickness and shapes are available at customers request