BRITCO TRANSFER POINT DESIGN

With revolutionary transfer point design technology, BRITCO makes transfer point problems a thing of the past. Providing unsurpassed conveyor and material handling knowledge, engineering capabilities and complete turn-key installation services.

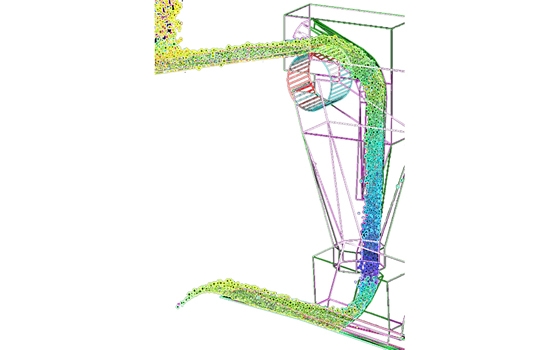

BRITCO 3-DEM CHUTE ANALYSIS PROGRAMRevolutionary Way To Handle Granular & Particulate Material Handling Problems BRITCOs 3-DEM (Discrete Element Methods) is a revolutionary way to handle granular and particulate material handling problems through computer simulation and 3-D CAD for complete transfer point design and fabrication.

Combined with our conveyor and material handling knowledge, engineering capabilities and 3-DEM Chute Design software are able to make transfer point problems a thing of the past.

* Increase Production Capabilities by helping to eliminate spillage, chute plugging, belt wear, dust control and noise.

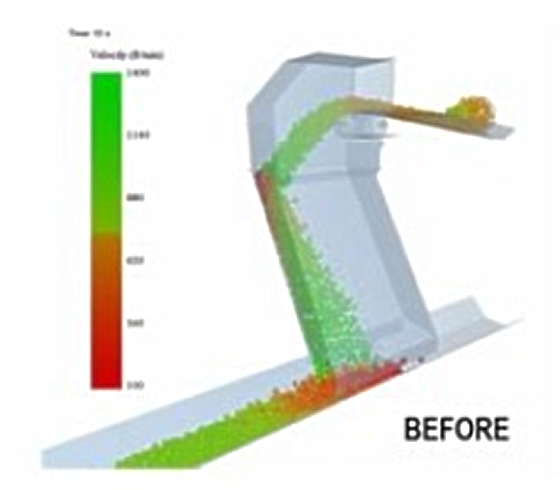

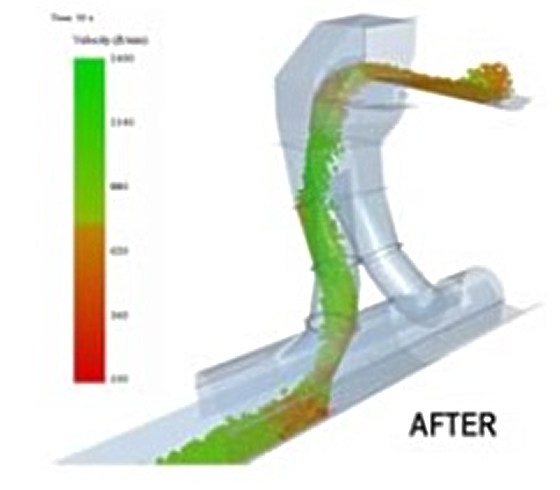

* Optimize Life on Conveyor Belt and Components by minimizing impact and top cover wear by using a soft or curved chute loading design.

* Minimize Material Spillage in the design by center loading the material, load the material at a uniform rate and optimize the material flow in direction of travel after the belt is fully troughed.

* Reduce the Need for Dust Control and Suppression by minimizing the dust through loading the material at a uniform rate through a curved of soft loading design, maintain effective skirting, internal wear liners and dust curtains staggered throughout the loading area

There are ten steps that need to be completed to have a trouble-free transfer point.1. Take current drawings of existing transfer and render them accurately in 3-D CAD.

2. Identify chute geometry restriction and manufacturing limitations.

3. Identify project goals (i.e. flow restrictions, dust emissions, optimize chute and belt life).

4. Identify material properties and develop representative particle description.

5. Make design changes to chute geometry.

6. Simulate performance using 3-DEMTM Chute Design software.

7. Evaluate simulation results and choose the best design that meets the project goals.

8. Detail the new design for manufacturing.

9. Manufacture the new transfer point including other conveyor components.

10. Installation of the new transfer chute and other conveyor components (i.e. belt cleaners, skirting systems and load zone beds or rollers).